Alle producten

-

Metalen spuitgietonderdelen

-

Deeltjes voor poederinspuiting

-

De Delen van de poedermetallurgie

-

Metalen gesinterde onderdelen

-

CNC-bewerkingsonderdelen

-

Verwerkingsonderdelen voor het draaien, frezen en bewerken

-

AEG-onderdelen Airsoft accessoires

-

onderdelen voor versnellingsbakken voor airsoftgeweren

-

Outdoor sleutelhanger gereedschap

-

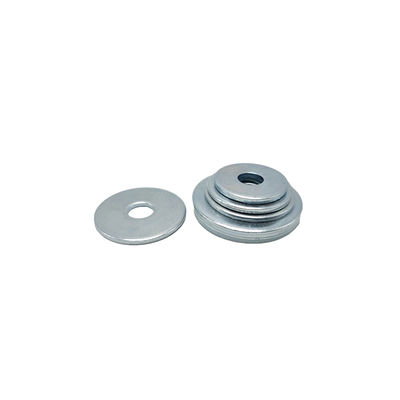

Flat gasket schem en wasmachines

Stainless Steel and Brass Shim Washers Flat Washers with 100% QC Inspection for Machinery Applications

| Plaats van herkomst | Guangdong, China |

|---|---|

| Merknaam | MDM |

| Modelnummer | MDM |

| Document | Productenbrochure PDF |

| Min. bestelaantal | 1000 |

| Prijs | $0.02-0.05 |

Contacteer me voor vrije steekproeven en coupons.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Als u om het even welke zorg hebt, verstrekken wij de online-Help van 24 uur.

xProductdetails

| Materiaal | Aluminium 6061/7075, roestvrij staal 304/316/420/303, messing, koper, titanium, koolstofstaal, zacht | Oppervlaktebehandeling | Anodization, zinkplaten, chroomplaten, nikkelplating, PVD -coating, polijsten, zandstralen |

|---|---|---|---|

| Techniek | CNC draaien, frezen, bewerken, boren, lasersnijden, stempelen, draadsnijden | Oppervlakteruwheid | Ra 0,8-3.2 |

| Tolerantie | 0,02 mm | Verwerkingsmethode | CNC-bewerking van draadwerken |

| Micro -bewerking | Geen microbewerking | CNC -bewerking | Ja |

| Maat | Aangepaste maten acceptabel | Kleur | Aangepaste kleuren |

| Materiële mogelijkheden | Aluminium, messing, brons, koper, geharde metalen, roestvrij staal, staallegeringen | Type | Braaching, boren, etsen / chemisch bewerking, laserbewerking, frezen, andere bewerkingsdiensten, dra |

| Moq | 100 | Verpakking | Polybag + binnendoos + doos |

| Kwaliteitscontrole | 100% QC inspectie | ||

| Markeren | Stainless Steel Shim Washers,Brass Flat Washers,100% QC Inspection Plain Washers |

||

Productomschrijving

Stainless Steel Shim Plain Washers Flat Washers Brass Shim

High-quality shim washers available in various materials including stainless steel and brass, suitable for industrial applications requiring precision spacing and alignment.

Product Specifications

| Material | Aluminum 6061/7075, stainless steel 304/316/420/303, Brass, copper, Titanium, Carbon steel, Mild steel, #45 steel, 4140, 4340, Kovar alloy |

| Surface treatment | Original or according to requirements: zinc plating, chrome plating, nickel plating, PVD coating, anodizing, polishing, sand blasting |

| Technics | CNC Turning/milling/machining/drilling/laser cutting/stamping/wire cutting |

| Sample | Sample costs can be refunded when mass production is confirmed |

| Surface Roughness | Ra 0.8-3.2 |

| Color | PVD black/silver/yellow/golden, black oxide, zinc plating black/silver/colorful etc. |

| Feature | Good quality, 100% inspection before shipping, sales guarantee 2 years |

Company Profile

Dongguan Minda Metal Technology Co., Ltd. was founded in 2015. We specialize in producing CNC machining parts, MIM parts, powder metallurgy parts, and aluminum/magnesium alloy die casting parts. We also undertake corresponding product mold design, development, and production.

Our professional sales staff communicates with customers to understand requirements, which are conveyed to technical staff for rapid quotation development.

During production, we conduct quality checks at every stage, with full inspection before shipment to ensure no defective products reach customers.

For hardware accessories solutions, contact us anytime - we're available 24/7.

Packaging & Shipping

Frequently Asked Questions

Q1. What kind of documents do you need for a quotation?

A: We need PDF drawings, 3D drawings files in STEP, IGS or X_T format

Q2. Can you make the parts according to samples?

A: Yes, we can. You need to send us the samples for assessment. We can establish the drawing model through physical samples and then use it during production.

Q3. What kind of materials are used on your products normally?

A: Aluminum, Steel, Brass, Stainless Steel, Bronze, Titanium alloy, etc.

Q4. Can you assemble the products?

A: Yes. We can assemble the products according to the assembly drawing requirements of the customers.

Geadviseerde Producten